+86 15633683072

a). The probe is heated to a specified temperature (usually 850 ° C), being inserted into the medium to be tested for cooling, cooling rate is recorded by a built-in microcomputer system, and the detection result is set by a four-color drawing printer. It is plotted as a cooling process curve (temperature/time) and a cooling characteristic curve (temperature/cooling rate). Results can also be printed as a tabular output. Performance of the medium is evaluated based on the above results.

a). The probe is heated to a specified temperature (usually 850 ° C), being inserted into the medium to be tested for cooling, cooling rate is recorded by a built-in microcomputer system, and the detection result is set by a four-color drawing printer. It is plotted as a cooling process curve (temperature/time) and a cooling characteristic curve (temperature/cooling rate). Results can also be printed as a tabular output. Performance of the medium is evaluated based on the above results.

b). Analysis principle:

Comparing the maximum cooling rate of the measured medium with the critical cooling rate of the workpiece determined in advance to determine whether the hardening ability meets the requirements and whether the medium should be replaced or adjusted;

c). The 300 ° C cooling rate of the measured medium is compared with the 300 ° C crack-free safe cooling speed of the workpiece determined in advance to determine the quenching tendency of the medium to the workpiece and whether the medium should be replaced or adjusted; the medium can be determined according to the cooling curve. Lower characteristic temperature.

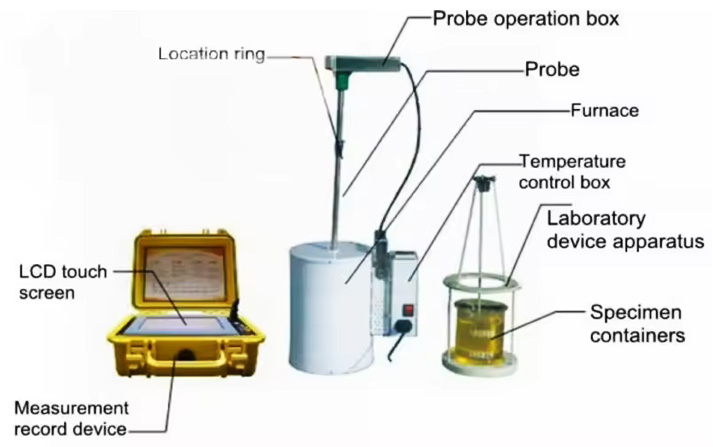

| Probe | Heating furnace | Measuring device | |||

| Probe body size | ∮12.5× 60mm |

Furnace type | Vertical tubular resistance furnace | Sampling speed | Max1000 times/S |

| Heating temperature | <900℃ | Measured maximum cooling rate | 2000℃/S | ||

| Probe length |

600mm | Heating time | <10min | LCD touch screen size |

8feet |

| Temperature control accuracy | ±1℃ | ||||

| power |

AC220V 50Hz,50W |

||||

| Probe thermocouple | 1.5mm WRNK |

power | AC220V,50Hz 1000W |

||

| size | 310×210×320mm | size | 290×250 ×130mm |

||

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com